Dixie Crouch: Professional Make-up Project

Silicone Moulds

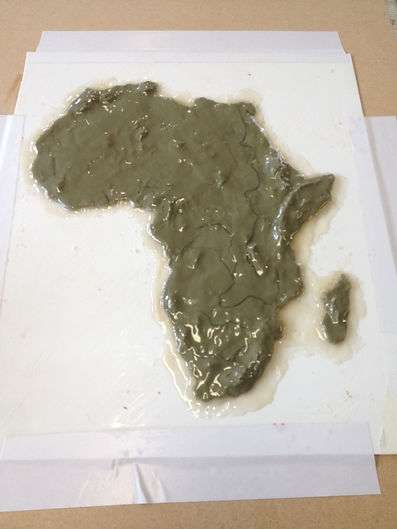

Although this is not a new techinique, i believe that these are some of the best silicone moulds that i have ever made. They came out really clean and i didn't have to trim them down or clean them up at all. I think that this was because of the time i took over the grounding up, and using the harder clay to do so. I am really happy with these moulds, and hopefully the pieces will come out good.

Fibreglass flat piece moulds

Moulding

Using the vibrosaw - Cleaning up edges

i love using the vibrosaw. I wanted to try and take a quick video of it, and try my time lapse out. Its a good way to promote. yourself, people on instagram love videos like this.

Cleaning Out My Moulds!!

I feel like an expert in cleanign out fibreglass moulds during this project. Since i had to clean out 5 of these pieces.

However i do not regret it, the practice was definitely worth it. and by the time i had got to the fifth mould i had the technique pretty down.

Things i learnt:

-DO not use boiling water out of the kettle onto your moulds because it will warp them.

-Do use a toothbrush. they are a lifesaver. or a thick bristled brush.

-Try and remove as much clay as possible with a curved sculpting tool, this will make the cleaning part easier.

-Use branded fairy liquid with warm water to remove the clay. (i also tried to use shampoo, and regular hand soap, but fairy liquid with a tootbrush seemed to work the best.)

-once the majority of the clay is removed, use polywax with a chit brush to remove the last of it. This also gives extra mould release for when it comes to running the pieces.

Also now i feel more confident about working in a workshop or a prosthetics studio and approaching industry professionals about work experience because it is more than likeky that they are going to have me cleaning out moulds and doing the lower jobs, and now i feel mo qualms about doing jobs like this because i have had all this practice.

When making flat piece moulds it is not common in industry to make fibreglass flat piece moulds.

There are reasons for this.

- In industry silicone is more likely to be used because film companies and studios have bigger budgets and allow for silicone flat piece moulds.

- Fibreglass moulds also take a lot longer to make that silicone moulds. silicone moulds can be ready within an hour, whereas fibreglass may take the whole day to make and then cure.

- You also have to take time to clean up, trim down and clean out the mould, which again takes time up where you can be running pieces.

- i think with care silicone mould can last just as long as fibreglass moulds.

And in all the research i did, there was not artist who made flat pieces from fibreglass. But i decided to go this route for a few reasons. (I spoke to wayne about this idea and he said it would work, as long as the sculpts did not have a lot of texture in them, if that was the cast it may be easier to make a silicone mould.)

-Budget. because i had 5 large pieces to mould i wanted to keep my budget down, to do this i think i would have run out of silicone.

-i also wanted to practice my fibreglassing, and i think with a simple mould this was the best way to get the technique right and perfect the skill.

Fibreglass reference from Stuart Bray

This is a fibreglass jacket made by Stuart Bray for one of his online tutorials. even though i am not making fiibreglass jacket, i thought that this was a great reference of thickness for me because in previous projects i felt that my fibreglass moulds were a little thick, and i want these ones to be really neat. so i tried to follow this when i made mine.